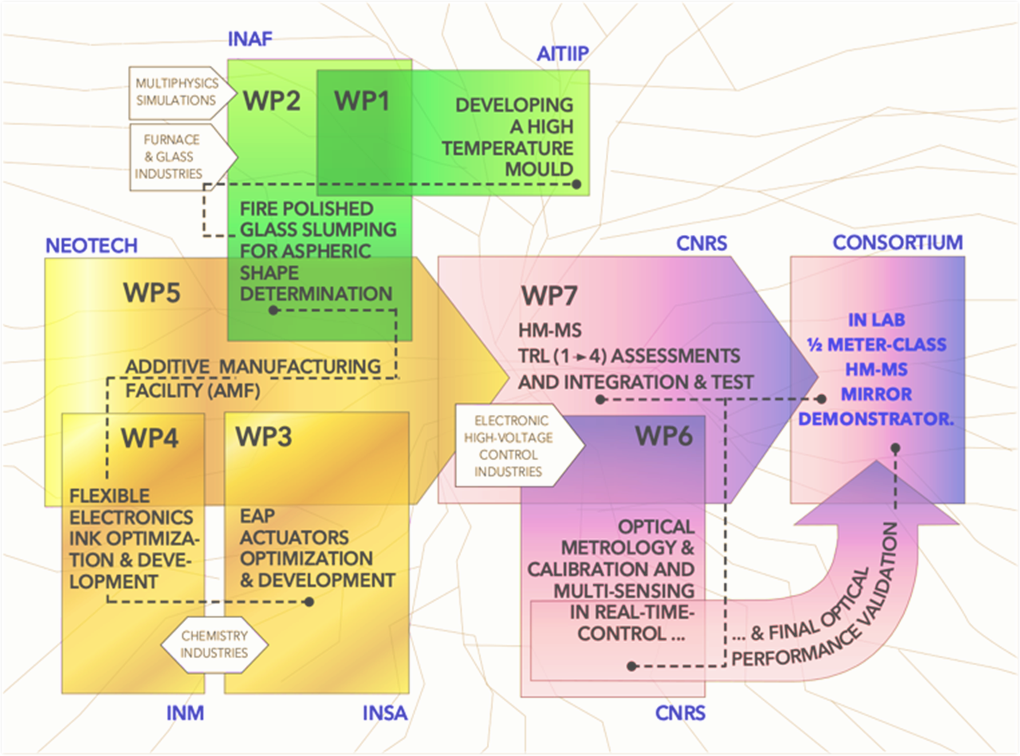

This newsletter updates partners on the EIC Live-Mirror team’s efforts, mitigation strategies, and progress during the project’s second year (2024). The update is organised according to the work packages that structure our consortium.

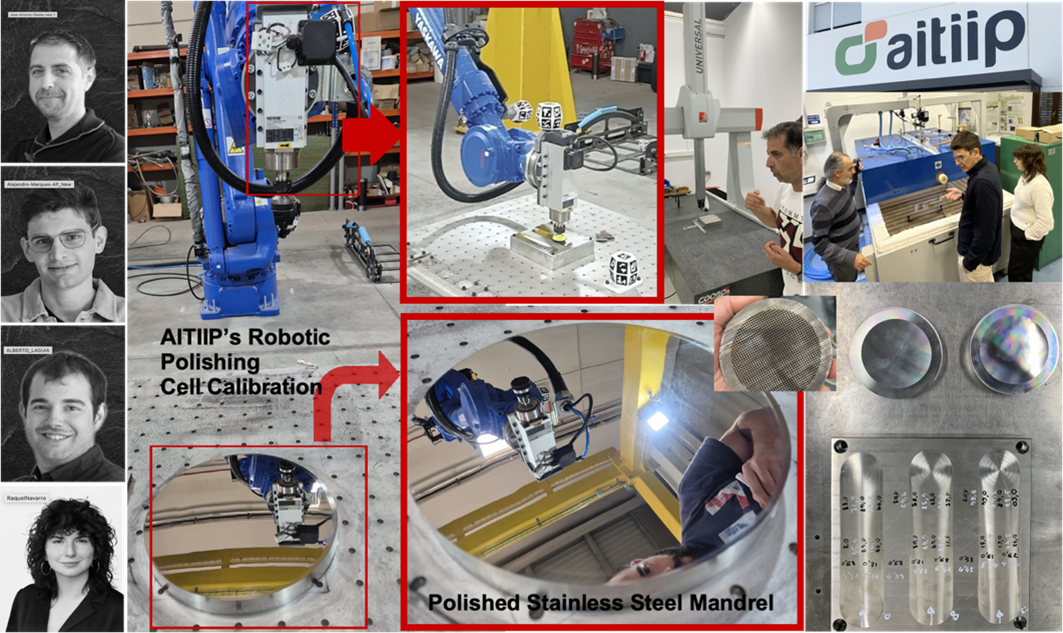

WP1 (AITIIP/Zaragoza) — DEVELOPING HIGH-TEMPERATURE MOLDS

The AIITIP team has made significant progress on the stainless-steel mandrel, including preliminary metrology work. Following the visit by Gil, Alejandro and Raquel to the INAF slumping facility in Merate in October 2023, Gil and Vincenzo visited AITIIP’s Zaragoza headquarters from July 29 to 31 for a brainstorming session focused on the stainless-steel mould and its testing procedures. José has reported that preliminary testing has been conducted in collaboration with the testing facility at Zaragoza University.

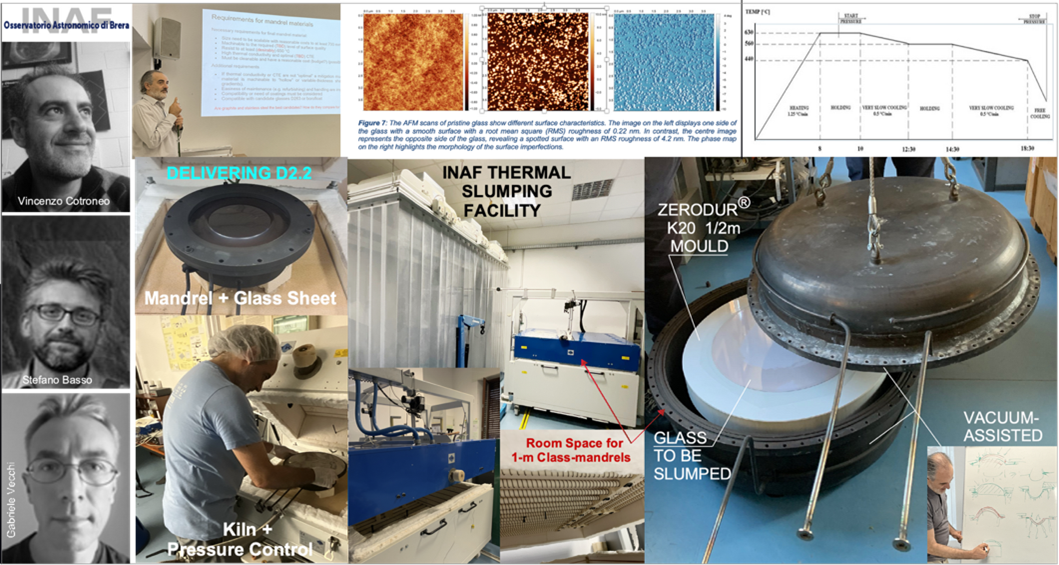

WP2 (INAF/Merate) — GLASS SLUMPING

The INAF team has been working on the first slumping glass using the INAF thermal slumping facility, which includes a 1/2-meter-sized kiln and a Schott® Zerodur ceramic mandrel. This effort aims to address the glass-forming process and its metrology. A preliminary sample has been delivered, and methods and tools for producing glass substrates have been outlined to support the project and explore potential improvements. Comprehensive metrology and characterisation of the glass substrates will be conducted before and after the thermal forming process. Deliverable D2.2 has been delivered, identifying specific methods and tools to characterise and quantify the results of the thermal forming activity.

Next, WP1 and WP2 will collaborate to establish the final testing strategy for the AIITIP’s mould’s optical shape and surface roughness. This mould is intended to be integrated into the thermal slumping facility at INAF. Furthermore, INAF will redefine the procedures for the slumping and testing of new Schott® Borofloat glass sheets, commencing with diameters ranging from 10 to 30 centimetres. Gil received the Research New Equipment Prize from the University of Lyon 1 in 2023. This grant has provided us with a new 4D NanoCamera Profilometer, which will be used to evaluate the surface roughness of Live-Mirror proof-of-concept models.

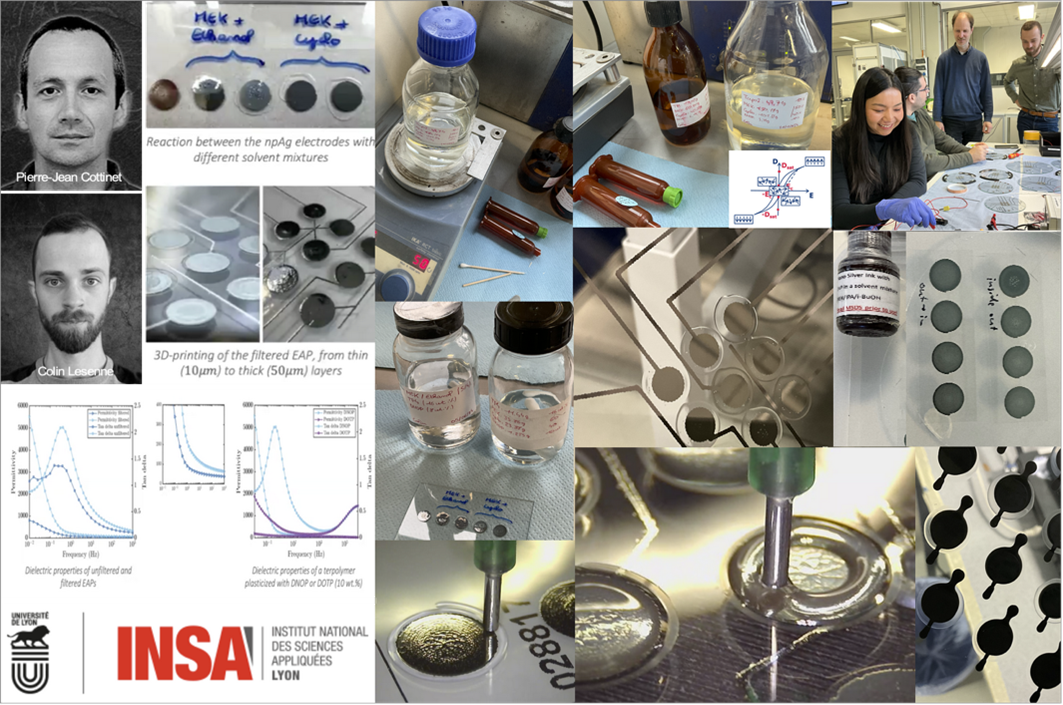

WP3 (INSA/Lyon) — EAP ACTUATORS OPTIMIZATIONS

The INSA team continues to advance the optimisation of electroactive polymer (EAP) materials through new processes in conjunction with terpolymer matrices and Arkema-France. The team is also exploring the use of doping. Samples have been delivered for the 3D Printing sessions in Nuremberg.

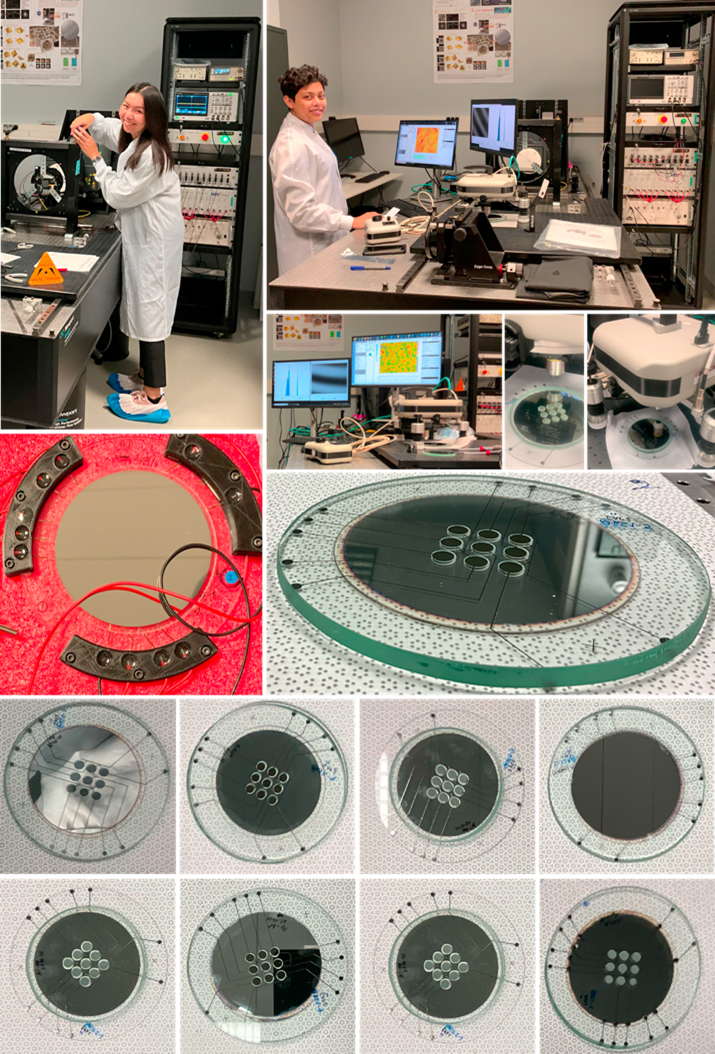

WP4 (INM/Saarbrücken) — FLEXIBLE ELECTRONICS INK OPTIMIZATIONS

The INM team focused on optimising silver nanowire inks. These tests were conducted locally using their Micro Drops Printer and subsequently at Nuremberg. During the 3D printing sessions in Nuremberg, the ink and the EAPs curing procedure were assessed. Additionally, INM has made significant progress on the silver optical coatings (as measured and confirmed by WP6 using the new 4D Nano Camera with RMS roughness between 0.2 to 0.3nm on a 1mm2 FOV). The team has also developed impressive 3D-printed mounts and supports (thanks, Mariano!) for the Live-Mirror proof-of-concepts montage and final control connections. In collaboration with an industrial (Master Bound, US), optimisations of the flexible glue’s Young modulus are done for various setup configurations to combine the optical (OS) and reaction (RS) surfaces.

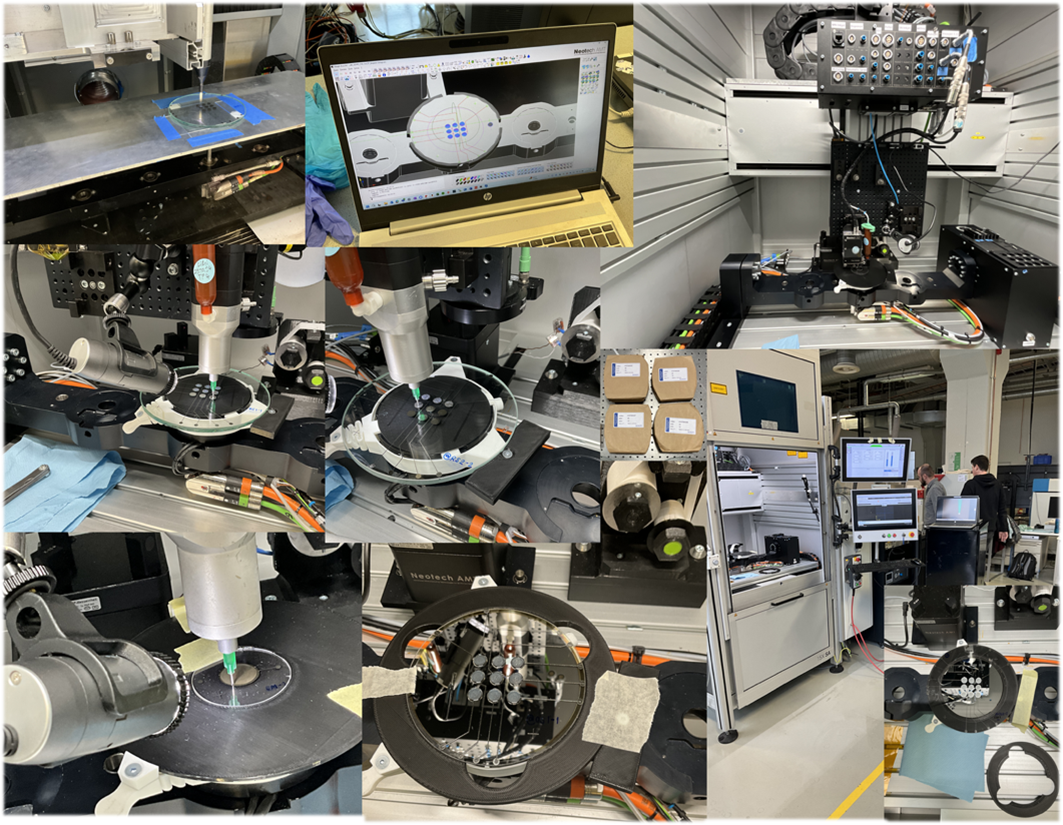

WP5 (Neotech/Nürnberg) – ADDITIVE MANUFACTURING FACILITY (AMF)

The Neotech team has made significant strides in optimising and developing the Additive Manufacturing Facility (AMF) for Live-Mirror proof-of-concepts. Their relentless focus on the reliability and feasibility of 3D printing of optimised EAP and flexible inks (WP3 + WP4) for Live-Mirror concepts has been instrumental in our progress. Three collaborative sessions were scheduled (February 19-23, September 9-13, and October 27-31) for 2024. These sessions involved teamwork among the EIC Live-Mirror coordination, the Neotech team (WP5), and teams from WP3, WP4, and WP6 at Neotech headquarters.

A new company, the Kronos Mechatronics GmbH, was created and registered in the trade register (HRB 43784 Amtsgericht Nürnberg) on November 25, 2024, with the stop operation of the Neotech AMT in December 2024. The new company’s operational and financial structure will enable it to contribute effectively to the EIC Live-Mirror project. Francesca and Gil are working with the EU EIC Project Officer on the amendment to include Kronos Mechatronics GmbH as a new partner in the EIC Live-Mirror project and to resume WP5 activities. In collaboration with WP3, WP4 and WP6, the Additive Manufacturing Facility is beginning to take shape and is on track for delivery, instilling confidence in the future of the Live-Mirror project.

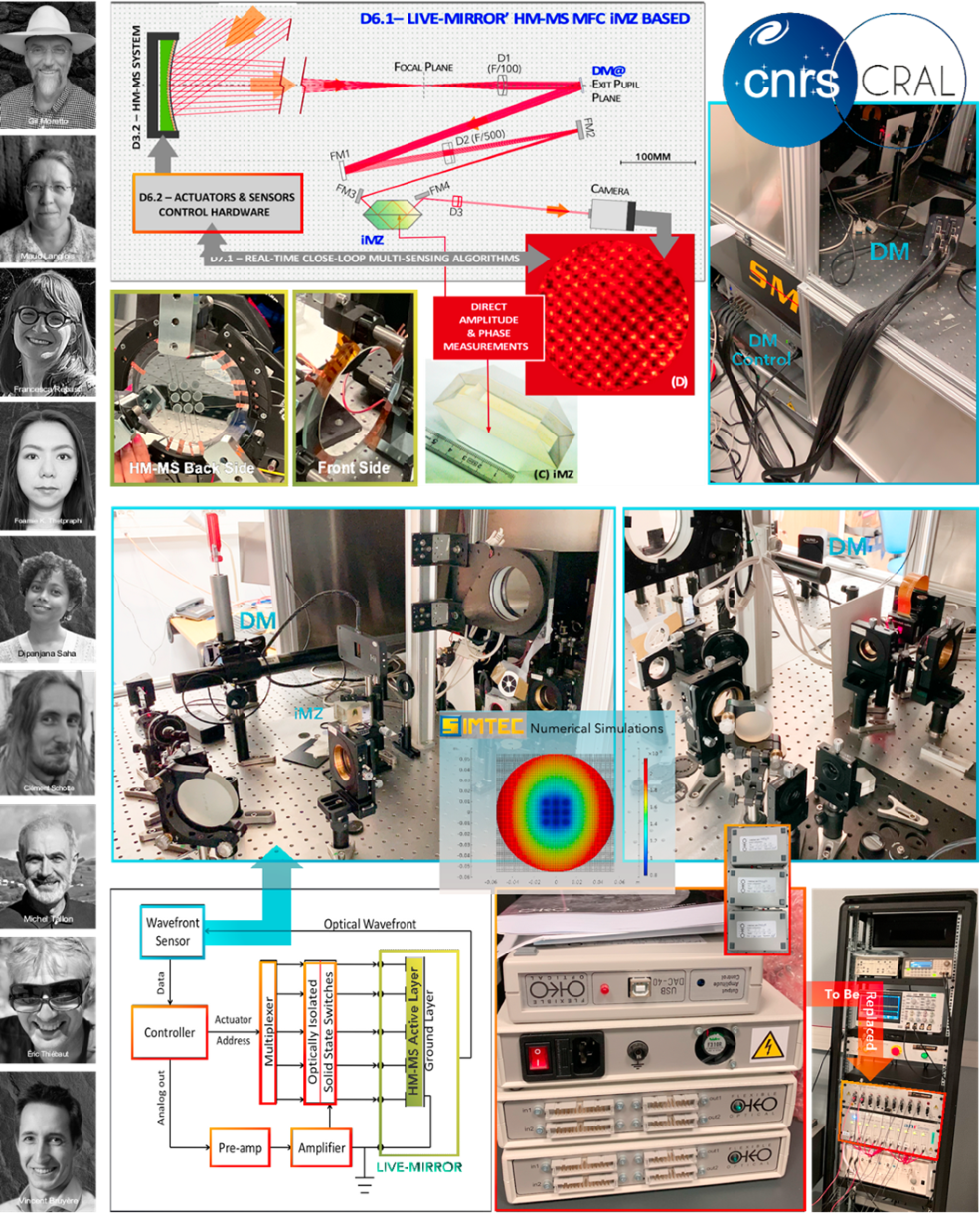

WP6 (CNRS/Lyon) – METROLOGY, CALIBRATION AND CONTROL

The CRAL/CNRS team is working on WP6, which focuses on optical metrology to measure optical wavefronts in the Live-Mirror proof-of-concept systems. In collaboration with the industrial Magéa in France, the team has developed a method for feeding and controlling 10 channels/actuators. This work represents a preliminary component version of Deliverable D6.2 (Low-Level Control Hardware On-Board System), which is dedicated to optical wavefront measurements aimed at evaluating and confirming the reliability and feasibility of the 3D printing procedure (WP5) for a set of actuators and their associated flexible electronics (as outlined in WPs 3 and 4).

Such reliability and feasibility of 3D printing represent a significant advancement in the project’s progression, focusing on developing larger proof-of-concept systems with diameters ranging from 30 to 50 cm and hundreds of actuators and incorporating slumped glass.

Also, in 2024, the CRAL team continued to advance the optical and control designs necessary for the final on-bench measurements and evaluations of the optical performance of the Live-Mirror proofs of concept. This WP6 initiative is based on precise multi-spatial and temporal-frequency-controlled surface metrology and calibration, providing essential data for operating hundreds of force actuators across various optical surfaces.

In close collaboration with OKO Flexible Optical BV in Rijswijk, Netherlands, the WP6 team has specified and optimised a high-voltage power supply along with an amplifier to manage and control hundreds of cards. This initial configuration consists of three sets of 40 channels and a USB DAC driver module, enabling real-time, closed-loop control of at least 120 actuators.

The Live Mirror requires more actuators to operate effectively on a slumped sheet of glass with a diameter of 0.5 meters. The team has streamlined updating the number of cards, highlighting the procedure’s reliability and reproducibility. Given the versatility and effectiveness of the on-bench Live Mirror for measurements, calibration, and control, the WP6 team has concentrated on optimising the opto-mechanical configurations for the On-Bench New iMz Optical Setup.

The recent developments include: (1) the specification of a custom deformable mirror (DM) featuring fast response, high-quality surface, and robust dynamic actuation from Bertin-Alpao, Grenoble, France. The DM has been delivered and is currently undergoing optical characterisation and qualification; (2) Two ½ meter off-axis parabolic (OAP) collimators have been tailored designed and specified by the team and ordered from YUDI Optics (Shanghai, China), with anticipated delivery set for May 15, 2025; (3) the qualification process for the camera and light source is scheduled to commence shortly in the first trimester of 2025; and (4) In close collaboration with SIMTEC (Grenoble, France), the team is addressing Multiphysics numerical simulations (COMSOL) to define the optimal distribution of actuators’ lattice.

Additionally, we are using the new 4D Nano Camera profilometer to characterise and evaluate the roughness quality of the glass and coatings for our proof-of-concept projects. In the first week of January 2025, we will initiate optical wavefront measurements, including assessments of optical surface roughness, for proofs of concept developed during our 3D printing session held in Nürnberg in October 2024.

WP8 (CNRS/Lyon) – COORDINATION

The EIC Live-Mirror Coordination Team, Francesca and Gil, actively manages and supports the project’s daily operations. Their proactive involvement has been essential in fostering effective collaboration, including organising and participating in monthly meetings with each work package of the Live-Mirror consortium. In-person visits to partners and EIC offices have enhanced our coordination, understanding, and progress in the Live-Mirror project.

The Coordination team and Maud (WP6 Leader) attended the EIC Pathfinder Day organised by the European Innovation and Executive Agency (EISMEA) on November 20, 2024. Based on the facilities and tools proposed in the meeting, our coordination team has scheduled a visit for January 17, 2025. During this visit, the coordination team, Peter William, Johannes and Maud (leaders for WP4, WP5 and WP6), will be visiting the EISMEA Headquarters in Brussels for a brainstorming session with Stela Tkatchova, the EISMEA Programme Manager for Space Systems and Technologies and Remus Ion Iacobescu, the EISMEA Project Officer/Experts Management. This collaborative meeting will focus on strategies to boost and qualify the EIC Live-Mirror for space and develop a spin-off to gain acceptance for the EIC Live-Mirror within the Transition program.

Francesca has been working on delivering and animating the EIC Live-Mirror consortium webpage (https://eic-live-mirror.eu/) with the help of Inês Antonio during her Master’s internship. An internal document will be sent to the consortium outlining how to keep our webpage active and updated.

ARRIVAL & DEPARTURES

The CRAL/CNRS team welcomed Dipanjana Saha as a postdoctoral researcher for two years starting in October 2024. Dipanjana earned her PhD from the Conservatoire National des Arts et Métiers (CNAM) in Paris, France. Her thesis focused on “Characterization of Material Surfaces Using a Multiscale Approach Based on BRDF Measurement.” In her new role, she will work on WP6 and contribute to developing metrology, calibration, and control systems for Live-Mirror concepts in a closed-loop and real-time context. Welcome, Dipanjana!

The CRAL/CNRS team welcomed Dipanjana Saha as a postdoctoral researcher for two years starting in October 2024. Dipanjana earned her PhD from the Conservatoire National des Arts et Métiers (CNAM) in Paris, France. Her thesis focused on “Characterization of Material Surfaces Using a Multiscale Approach Based on BRDF Measurement.” In her new role, she will work on WP6 and contribute to developing metrology, calibration, and control systems for Live-Mirror concepts in a closed-loop and real-time context. Welcome, Dipanjana!

Foamie Kritsadi Thetpraphi, a researcher in science materials, played a crucial role in the initial concept and development of the Live-Mirror project in 2017. She completed her PhD thesis, “Development of Electroactive Polymer Actuators for Next Generation Mirror: Live-Mirror”, at the Institut National des Sciences Appliquées (INSA) Lyon, France, in 2020. After more than three years of dedicated research and development on the Live Mirror, she became an Associate Professor at the School of Science, Walailak University in Thailand. Starting in September 2024, we welcomed her back as an external expert partner to the EIC Live-Mirror consortium. Foamie’s unwavering dedication is evident as she contributes to projects via Zoom and during extended visits when she is not teaching. Throughout October 2024, she travelled back to CNRS/Lyon to work with us. Thank you, Foamie, for your hard work and commitment to the project’s success.

Foamie Kritsadi Thetpraphi, a researcher in science materials, played a crucial role in the initial concept and development of the Live-Mirror project in 2017. She completed her PhD thesis, “Development of Electroactive Polymer Actuators for Next Generation Mirror: Live-Mirror”, at the Institut National des Sciences Appliquées (INSA) Lyon, France, in 2020. After more than three years of dedicated research and development on the Live Mirror, she became an Associate Professor at the School of Science, Walailak University in Thailand. Starting in September 2024, we welcomed her back as an external expert partner to the EIC Live-Mirror consortium. Foamie’s unwavering dedication is evident as she contributes to projects via Zoom and during extended visits when she is not teaching. Throughout October 2024, she travelled back to CNRS/Lyon to work with us. Thank you, Foamie, for your hard work and commitment to the project’s success.

Inês Antonio was a Master’s intern from Université de Lyon 1, Scientific and Technical Communication Program, following a Bachelor’s degree in Information and Communication. She worked with us (WP8) for six months to develop the EIC Live-Mirror website. Thank you, Inês, for your hard work in creating such an outstanding website. We wish you the best in your future endeavours.

Inês Antonio was a Master’s intern from Université de Lyon 1, Scientific and Technical Communication Program, following a Bachelor’s degree in Information and Communication. She worked with us (WP8) for six months to develop the EIC Live-Mirror website. Thank you, Inês, for your hard work in creating such an outstanding website. We wish you the best in your future endeavours.

The INAF team (WP2) is hiring a PhD student to work on Thermal Slumping Assessments under Vincenzo’s direction. We expect to have updated information by early 2025.

¡Muchas Gracias! — Les deseo un maravilloso y próspero Año Nuevo lleno de alegría.

Grazie di cuore! — Vi auguro un nuovo anno meraviglioso e prospero, pieno di gioia!

Merci beaucoup! — Je vous souhaite une merveilleuse et prospère nouvelle année remplie de joie !

Vielen Dank! — Wir wünschen Ihnen ein wunderbares und erfolgreiches neues Jahr voller Freude!